SF6 relay communicates with the gas chamber and monitors the density of the sealed equipment container (gas chamber). The performance of insulation and arc extinguishing (circuit breaker gas chamber) depends on the density and purity (impurities, moisture content) of SF6.

The SF6 relay gauge pointer indicates pressure, why is it called a density meter

The SF6 relay pointer we see indicates pressure/Mpa, (1 atmospheric pressure is approximately equal to 0.1Mpa). So why is it called a density relay?

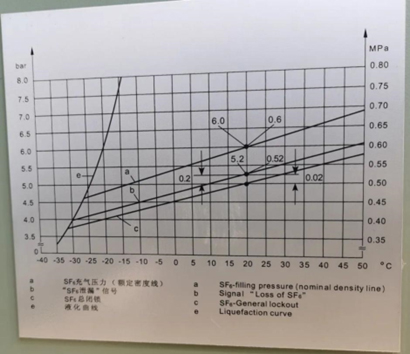

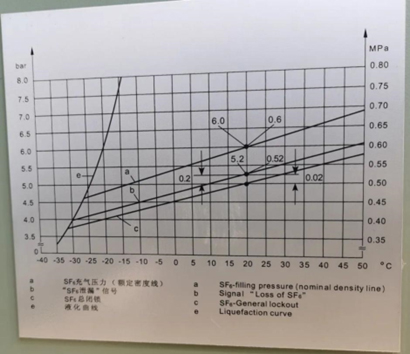

The gauge shows Setting Temp +20℃, if the ambient temperature is not 20℃, the internal elastic mechanism of the gauge compensates for pointer displacement with temperature changes. This ensures that regardless of the ambient temperature, the pointer always shows the SF6 pressure at 20℃, and this pressure is only related to gas density. There are also old-style gauges without temperature compensation. Their dial scale has no red and green colors, but they provide a temperature/pressure curve for you to refer to and see what the normal pressure should be at the current temperature.

Who uses the pressure contact provided by the SF6 relay?

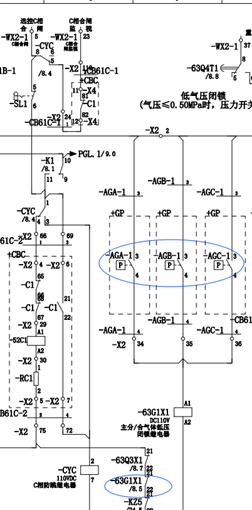

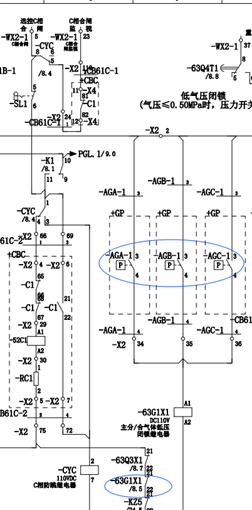

As you can see from the dial, the SF6 relay has 3 pressure contacts. The output is led out to the terminal strip for users to use as needed.

For the circuit breaker gas chamber, there are rated values, alarm values, and lockout values; for other chambers, there are only rated values and alarm values. Additionally, the rated value for the circuit breaker gas chamber should be slightly higher than that of other chambers. The pressure contact of the circuit breaker gas chamber is connected to the low-pressure interlocking relay circuit, and the auxiliary contact of the relay is connected in series with the control circuit of the circuit breaker. When the pressure drops to the lockout value, the auxiliary contact in the control circuit interrupts the circuit breaker's opening and closing circuit (total lockout), sending a signal indicating a disconnection in the control circuit. (The hydraulic gauge circuit operates on a similar principle.)

What to pay attention to during the operation of SF6 relay?

Ensure that the meter is equipped with a rain cover to prevent water ingress and dampness, which may lead to inadvertent signaling of contacts.

The valves connecting the meter and the main body should remain open.

Even with excellent sealing, SF6 density relays still have a certain leakage rate. If the valve is closed and the gas inside the meter is minimal, a leak without replenishment can lead to a rapid pressure drop inside the meter. This triggers an alarm signal and may even result in the lockout of the circuit breaker's opening and closing operations. Therefore, after maintenance personnel complete gas replenishment and SF6 trace water detection, it is crucial to ensure that this valve is properly opened.

Phenomenon:The monitoring system issues an alarm or lockout signal for SF6 gas pressure, or the pressure indication on the SF6 pressure gauge decreases.

Handling Principles:Conduct on-site inspection of the external appearance of the SF6 pressure gauge and check if the gas pipeline valves are in the open position.

If the monitoring system issues a low-pressure alarm or lockout signal, but on-site inspection shows that the SF6 pressure gauge indicates normal pressure, consider it a false signal and contact maintenance personnel for resolution.

If the SF6 pressure has indeed decreased to the alarm value but not yet reached the lockout value, contact maintenance personnel for resolution.

After gas replenishment, check the opening and closing positions of the SF6 pipeline valves and monitor the pressure changes in SF6.

If the SF6 pressure has indeed dropped to the lockout operation pressure or directly to zero, immediately disconnect the operating power, lock the operating mechanism, and promptly report to the on-duty control personnel to request isolation of the faulty combined electrical apparatus.

Related Article for Reference